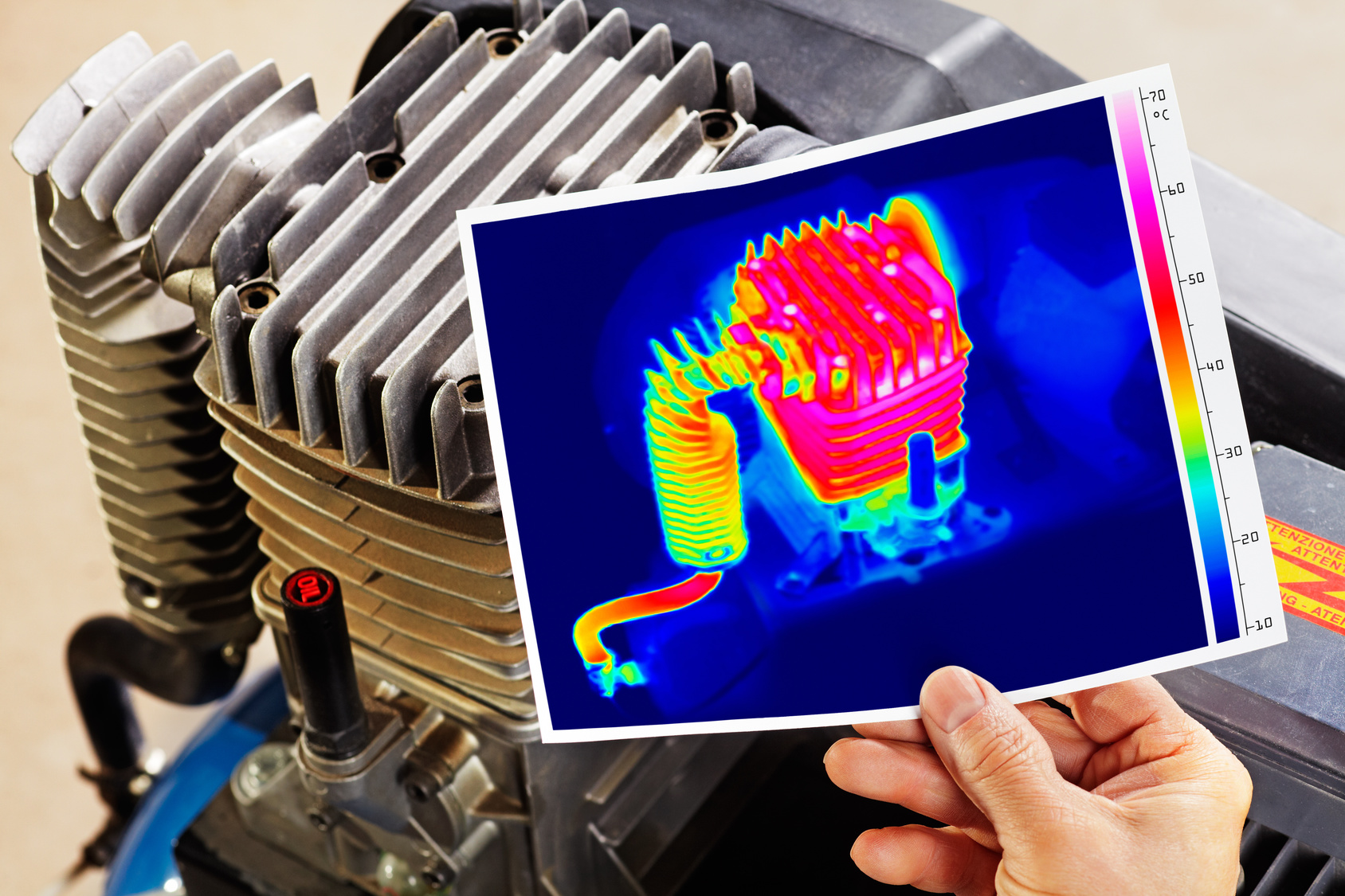

MECHANICALResponding to the direct impacts of temperature on mechanical efficiency

Oil viscosity, constant lubricant film, ARIAMIS studies the means to maintain the ideal temperature range, a guarantee of performance and the limitation of mechanical wear.

IDEAL OIL VISCOSITY DIRECTLY DEPENDS ON THE TEMPERATURE

Oil’s lubricating power is directly influenced by the temperature. When it is too cold, it does not lubricate effectively. When it is too hot the oil deteriorates, either slowly by oxidising and generating particles, or quickly when the oil “cracks”. Thermal management tries to reach the ideal temperature range as quickly as possible and then keep it there. An even finer thermal management will not be content to reduce the risk of malfunctions, but will aim to more precisely adjust the ideal operating temperature.

THE PHYSICAL EXPANSION OR CONTRACTION OF MECHANICAL PARTS

The relative expansion or contraction of parts in relation to each other leads to a change in the space between them. To be effective, the oil creates a lubricating film between the moving surfaces to minimise contact. This film must be constant to prevent friction that can cause a loss of efficiency and mechanical wear.

WATER, TO HEAT OR COOL THE OIL DEPENDING ON THE SITUATION

Water heats and cools very quickly, as opposed to oil that suffers from a certain level of temperature inertia. Oil is long to heat and gains in temperature until its combustion. Thermal management consists in foreseeing and organising calorie exchanges between the oil and the water.

> Sizing > Load loss > Water flow > Outside air > Temperature requirement > GMV

|

ENERGY MANAGEMENT

Warming, cooling or keeping at constant temperature, an objective shared by an entire system.

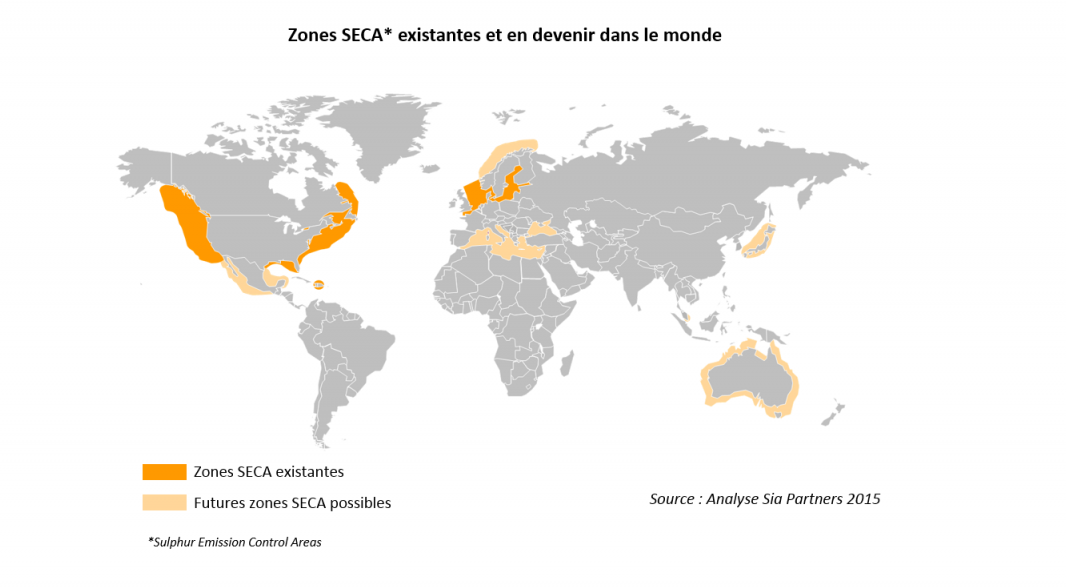

SEA

Liquid natural gas is increasingly seen as a solution that is both economic and ecological compared to heavy fuel.

ENGINE LUBRICATION

The right engine oil firstly implies the correct thermal control of all the fluid circuits |