RESEARCHFinding tomorrow’s turnkey solutions: more than a duty, a passion

By making thermal engineering its core business, ARIAMIS has achieved a solid specialist legitimacy with its manufacturing clients. A legitimacy that the design department maintains by regularly investing 10% of its turnover in research and development.

PROJECTS AROUND A SHARED PASSION

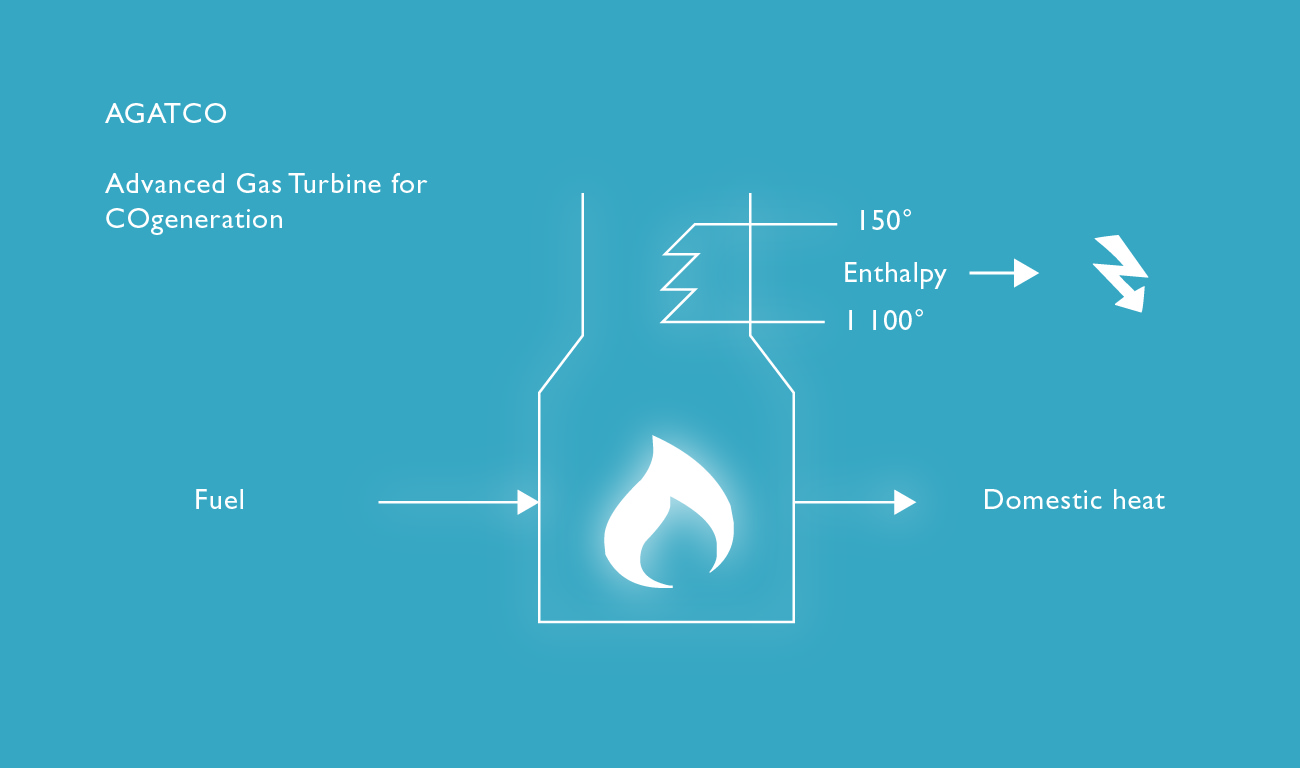

Thermal engineering is a challenge for the future as well as being an excellent driver of technological progress. This has been ARIAMIS’s belief since it was created in 2004. It organises its team of PhDs and engineers who, depending on their degree of specialisation, are involved in national research projects. Some have even resulted in patents being registered, such as the MOTHERA project which consists in optimising the MILLER cycle on controlled ignition combustion engines. More recently, the AGATCO project transposed ARIAMIS thermal engineering expertise to an individual wood boiler by using the enthalpy effect using a turbine to generate electricity. Currently in the prototype phase, this project was financed by the French Agence National de la Recherche.

PLAYER AND COORDINATOR OF INNOVATION

The ARIAMIS team, which is well versed in production phase projects, uses “smart community” principles as a coordinator and organiser. This is especially the case for the SAGAN project in which ARIAMIS supervised the development of a light utility vehicle running on compressed natural gas, for which it received an award from the Ile-de-France region. Finally, the design department works with its clients on the research and development of innovating solutions that result in patents being registered by the manufacturers.

|

RADIATOR

Thermal engineers to support you in specifying and sizing radiators adapted to your cooling needs BATTERY COOLING

Assessing thermal solutions as accurately as possible to guarantee the optimum use of each battery optimal de chaque batterie AIR CONDITIONING

Optimising air conditioning behaviour using a sufficiently fine thermo-management of each HVAC component

|