ENERGY MANAGEMENTWarming, cooling, keeping at constant temperature, this is ARIAMIS’s core action.

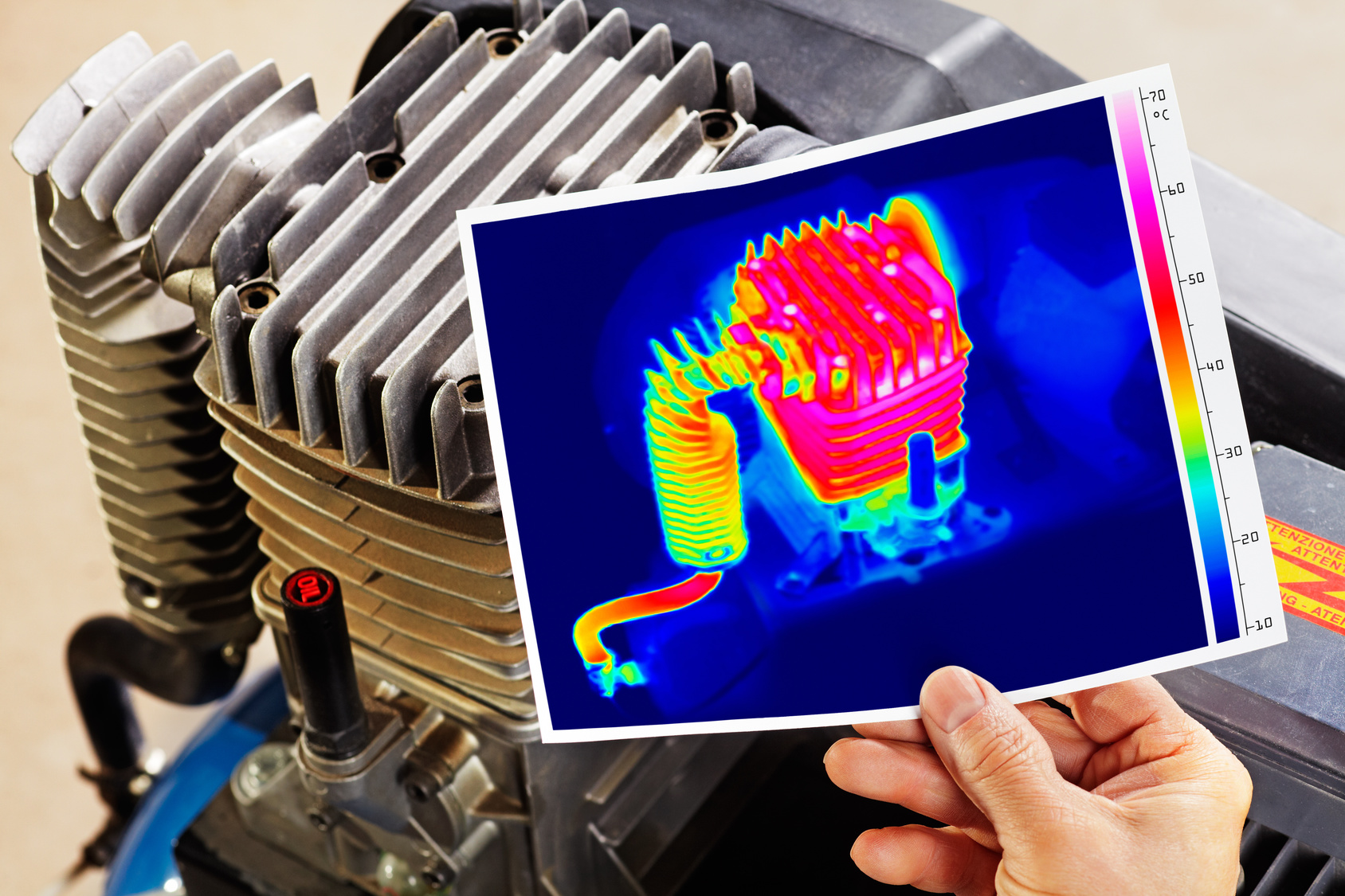

Energy management is ARIAMIS’s main expertise. Whatever the industrial world or context of use, there is always an ideal temperature. All ARIAMIS engineering is involved in understanding and organising the different interactions between system components to maintain this ideal temperature.

UNDERSTANDING INPUT DATA THROUGH MODELLING

Energy management covers different types of systems from all sectors of industry. To share the methodology that ARIAMIS proposes, we will take an example from energy management applied to the automotive sector. If it is easy to understand that there is an ideal temperature range for travellers, we should also understand that for the engine and a high number of other vehicle components, there is also an ideal temperature range (see the articles on efficiency). The initial phase of an energy management study consists in modelling the entire system. Knowledge of the materials, physics laws in mechanics, hydraulics, thermal engineering (transfers through convection, conduction and radiation) and all the parameters right up to the vehicle design are the input data for the problem represented by a model, so-called system modelling.

ANTICIPATING BEHAVIOUR THROUGH SIMULATION

Using modelling we put the notion of dynamics into play. Taking into account the different usage profiles makes it possible to anticipate behaviour. Start-up, full speed or low speed, different system behaviour orders correspond to each usage situation. The elements that play a role in the heating or cooling of car engines are the fan unit, the heat exchanger and the flow of coolant in the circuit. Simulation makes it possible to calibrate the different subsystems (fan motor power, coolant circuit pump power, control component, temperature sensor, pressure sensor, etc.).

ORGANISING AND CONTROLLING ENERGY MANAGEMENT THROUGH THE DEFINITION OF COMMAND LAWS

The purpose of energy management will be to maintain the ideal temperature in all usage situations. To achieve this, a calculator connected to a series of sensors will send the suitable commands: increase the coolant flow, increase the motor fan speed or on the other hand, privilege engine heating and prioritise it over passenger compartment heating when starting up. All these situations and the associated commands are formalised into command laws.

|

TALENT

Amongst the aptitudes of all ARIAMIS employees is a high level of specialisation and a strong capacity to adapt.

THERMO MANAGEMENT

Even though rarely considered to be a primary function, thermo-management is nevertheless an essential parameter in terms of emissions, performances and consumption

ENGINE LUBRICATION

The right engine oil firstly implies the correct thermal control of all the fluid circuits |